Company Profile

Established in 1989, FOREVER JUMBO has over 30 years of experience in the machinery industry. With a dedicated team of 20 employees, we have always upheld the core values of professionalism and integrity since our founding.

In our early years, we focused on providing precision machining services for mechanical components across various industries. Over time, we built a strong foundation and accumulated extensive technical expertise in the field.

Over the past three decades, we have had the privilege of working with international clients from Germany, Switzerland, Denmark, the United States, Japan, and other countries. These collaborations in manufacturing precision components have broadened our technical vision and strengthened our global operations. In addition to manufacturing, we also assist clients in mechanical design and automation development, offering integrated solutions tailored to their needs.

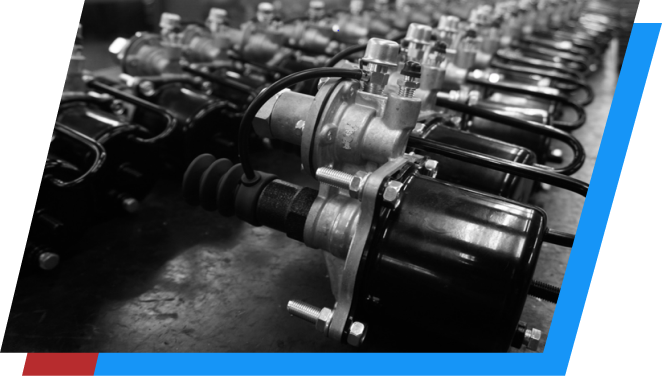

More than ten years ago, we began a successful partnership with a Taiwan-based trading company to develop repair kits for brake boosters and power brakes for Japanese vehicles. This long-standing collaboration has resulted in the shipment of over 285,000 units, reflecting our consistent product quality and reliable supply capabilities.

Driven by our evolving business philosophy, we have since taken the initiative to expand into the global market under our own brand. Our goal is to deliver high-quality, high-value products and services while building long-term, stable partnerships with customers worldwide.

Looking ahead, we remain committed to professionalism and pragmatism, creating greater value for our customers through continuous innovation to meet the diverse needs of the market.

Though our team is compact, our solid mechanical expertise gives us the flexibility and responsiveness to tackle various challenges. We strictly follow OEM manufacturing standards and processes to ensure stable and consistent quality. Our factory is equipped with a wide range of machining tools and advanced inspection instruments, allowing us to achieve an optimal balance between quality and cost.

In our early years, we focused on providing precision machining services for mechanical components across various industries. Over time, we built a strong foundation and accumulated extensive technical expertise in the field.

Over the past three decades, we have had the privilege of working with international clients from Germany, Switzerland, Denmark, the United States, Japan, and other countries. These collaborations in manufacturing precision components have broadened our technical vision and strengthened our global operations. In addition to manufacturing, we also assist clients in mechanical design and automation development, offering integrated solutions tailored to their needs.

More than ten years ago, we began a successful partnership with a Taiwan-based trading company to develop repair kits for brake boosters and power brakes for Japanese vehicles. This long-standing collaboration has resulted in the shipment of over 285,000 units, reflecting our consistent product quality and reliable supply capabilities.

Driven by our evolving business philosophy, we have since taken the initiative to expand into the global market under our own brand. Our goal is to deliver high-quality, high-value products and services while building long-term, stable partnerships with customers worldwide.

Looking ahead, we remain committed to professionalism and pragmatism, creating greater value for our customers through continuous innovation to meet the diverse needs of the market.

Though our team is compact, our solid mechanical expertise gives us the flexibility and responsiveness to tackle various challenges. We strictly follow OEM manufacturing standards and processes to ensure stable and consistent quality. Our factory is equipped with a wide range of machining tools and advanced inspection instruments, allowing us to achieve an optimal balance between quality and cost.

Our Services

Our current machining and quality control equipment includes:

1. 20 CNC machining centers

2. ZEISS CMM from Germany

3. Mitutoyo contour measuring system from Japan

4. Mitutoyo roundness tester from Japan

5. Surface roughness tester from Germany

6. Two Japanese-made hardness testers

1. 20 CNC machining centers

2. ZEISS CMM from Germany

3. Mitutoyo contour measuring system from Japan

4. Mitutoyo roundness tester from Japan

5. Surface roughness tester from Germany

6. Two Japanese-made hardness testers